Our processing

“It takes 20 years to build a reputation and five minutes to ruin it. If you think about that, you’ll do things differently".

(W. Buffett)

“It takes 20 years to build a reputation and five minutes to ruin it. If you think about that, you’ll do things differently".

(W. Buffett)

Our production lines are designed and developed with a view to ensure maximum efficiency: this allows us the flexibility, necessary to run small productions while maintaining the economies of scale of industrial productions, always guaranteed the solution with the best compromise in terms of technical content, reliability of the result and quality/price ratio.

Know how acquired by experience

All raw materials as well as all finished products are checked in our laboratory before approval for use in production or for shipment to customers.

We produce what you receive!

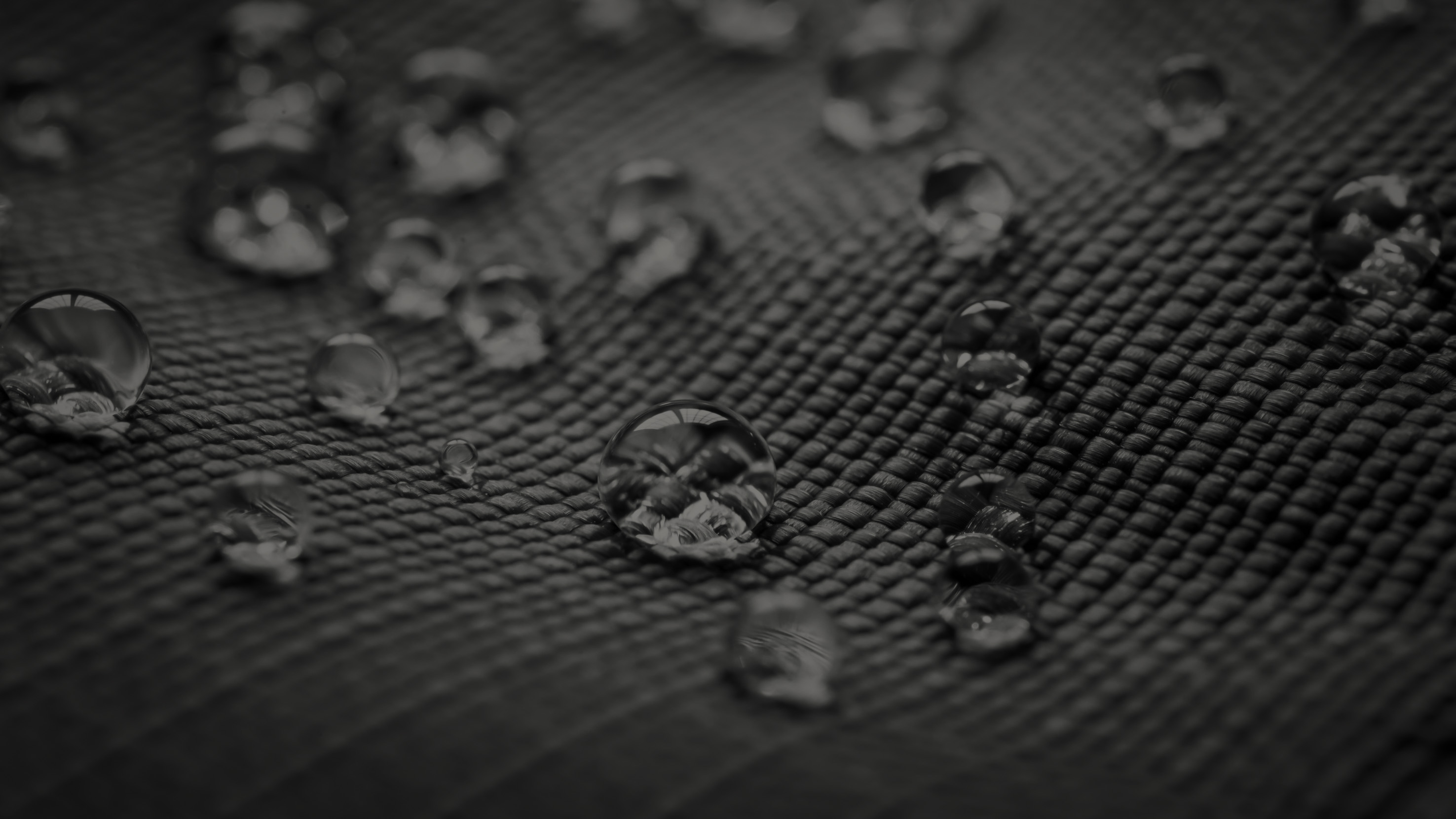

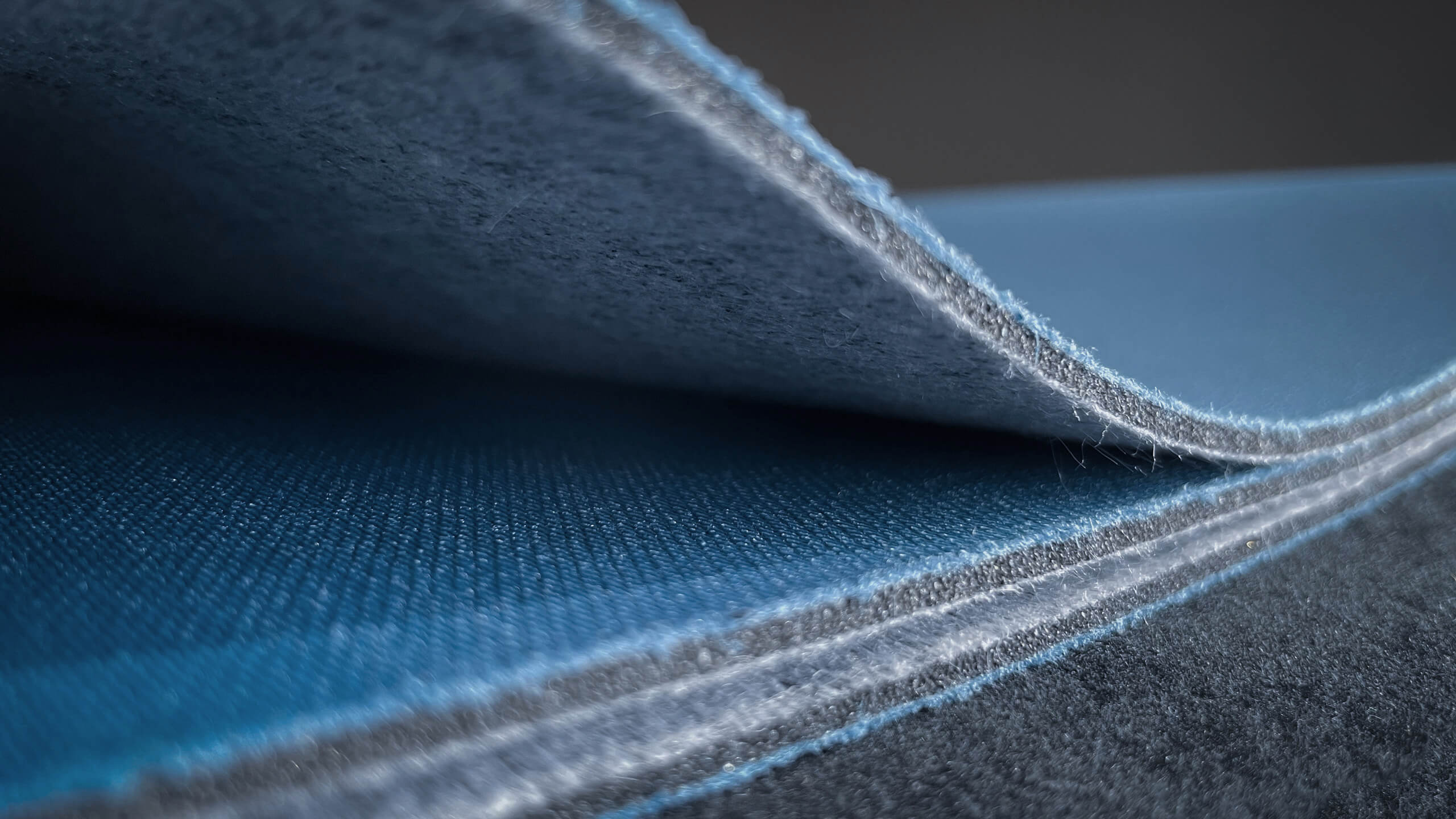

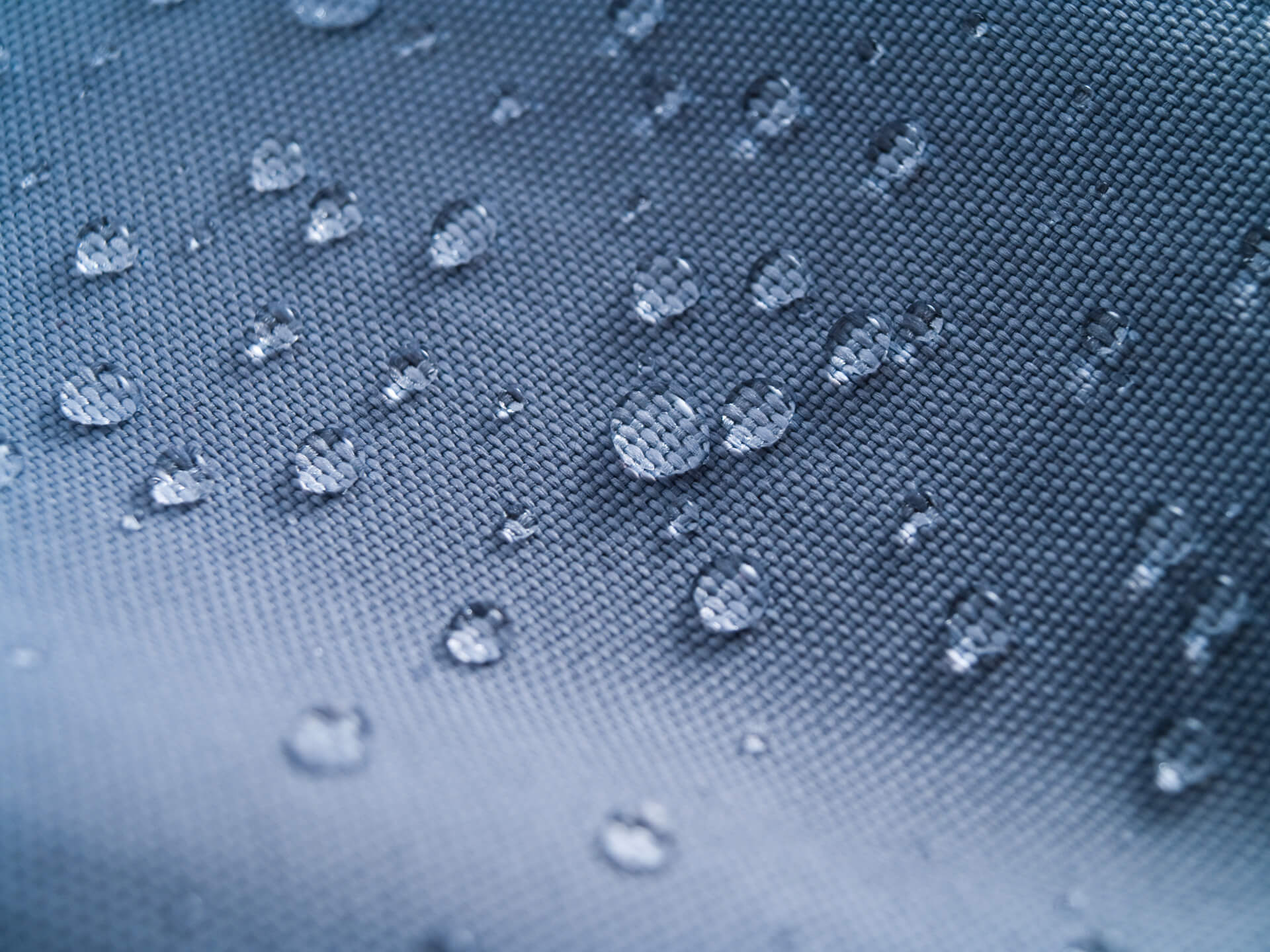

We offer different finishing that attribute different technical properties to fabrics, our in-house finishing line allows us to have maximum effectiveness and to guarantee the quality of the treatment thanks to rigorous laboratory tests verified for each production.

RCP customization

Thanks to our internal printing division we meet customer's expectation being able to design customized patterns and graphics, study placements to optimize the yield of printing on the fabric.

The projects will be followed from the graphic development to the finished, laminated and water-repellent product in order to provide a single responsability garanteed by rigorous control of the quality factor for each print to ensures continuity over time.

Furthermore, digital printing does not include the burden of fixed installation costs, guaranteeing short term delivery for limited editions.

During the entire prodution process, operators perform compliance checks with the master samples in order to verify accordance to the approved control plans.